Wood flooring is a versatile material that can last centuries if adequately taken care of. Homes dating back more than a hundred years still have their original wood flooring. To keep floors looking their best throughout this significant lifespan, occasional sanding is necessary.

Sanding is a process that can help bring new life into your old flooring and other wood objects, like decks. To accomplish sanding on large projects, people use wood floor sanders.

Choosing the right wood floor sander for your project is vital if you want the best results. Continue reading to learn everything you need to know about choosing an appropriate sander for your project.

What's the Purpose of a Sander?

A floor sander helps remove wood's old finishes. It does this by removing the top layer of wood and getting down to the substrate base of flooring or other projects.

Once the wood has been sanded down, it's a blank canvas and can be altered as desired. All (or most) necks, scratches, and indents will be removed. Wood should be sanded before refinishing, resealing, or redesigning.

Choosing the right sander is vital to the success of your project. Using improper equipment can lead to damaged floors or incomplete projects. Likewise, a bad sanding job (even when using the right equipment) can kill the wooden material's lifespan, look, and functionality.

Know the Types of Sanders

There are several types of sanders you could choose for your next project. Each has a unique set of benefits and downsides. Below are the most commonly used sanders and when they're most appropriate.

Disc Sander

An average disc sander is the most common choice. These machines use a sanding disc or buffing pad to remove old finishes. They can also be used to level out uneven flooring.

Disc sanders generally operate at high speeds, however, which can make them challenging to control. If you're not a professional, it's highly recommended you practice using the disc sander before tackling your project.

Palm and Vibratory Sanders

These are smaller sanders that usually provide less power versus disc sanders. Both palm and vibratory sanders are an excellent choice for those without a lot of experience using sanding machines.

You'll want to ensure you're not applying too much pressure when using palm and vibratory sanders. If you do, your efforts could leave behind cross-grain marks in the wood.

Handheld Belt Sanders

A handheld belt sander is perfect for working in smaller areas like deck railing tops. These machines are lightweight and more comfortable to handle than their larger counterparts.

Handheld Edgers

Another handheld option, these edgers are designed to work along floor edges. They're a lighter, smaller commercial option that can be difficult to control for inexperienced users.

Edgers, however, are necessary for any project. By enabling corners and other hard-to-reach areas to be fully sanded, handheld edgers ensure a complete, professional-looking result.

Commercial Drum Sanders

DIYers should avoid all commercial floor sanders unless they have extensive sanding experience. A commercial drum sander, for example, can remove a lot of wood at once. This fast, heavy removal process can damage wood decking or flooring if you aren't careful.

Commercial Vibratory and Orbital Sanders

For professionals, commercial vibratory and orbital sanders can be easier to control than drum sanders. The downside is these machines are typically hefty and can weigh up to 100 pounds.

This weight makes it difficult to transport or haul the sanders without a dedicated team and vehicles. It's dangerous to attempt moving these sanders around by yourself.

Choose an Appropriate Sander for Your Experience Level

Sanders are machines that can be difficult to control. Commercial floor grinders and sanders provide the most power and should only be used by professionals. Smaller machines range in difficulty, so consider what your experience level with these machines is.

Although choosing a more powerful, complicated machine may sound like it'll do a better job, it won't in the wrong hands. It's easy to damage flooring and other wood surfaces with a sander you aren't ready to use.

Choose a Low Speed for Working With Wood

Some sanders are designed for use on concrete, and these require higher speeds because the surface is more difficult to grind. Wood, however, is soft and requires a lower speed. Using too high a speed on wooden surfaces can cause significant damage, including erosion of the natural grain.

An excellent option for wood sanding is the OF16S. It's a 16" sander that can be used for sanding interior floors and smoothing exterior decks. With 120V power and a low speed of 500rpm, it's an excellent choice for beginners and powerful enough for contractors.

A similar alternative is the OS2OS-L120 machine. It also has a low speed of 500rpm combined with 120V power. The difference is that this machine is 20" and can make shorter work of large areas.

Consider a Multi-Use Tool

Multi-use tools are something to be considered if you'll use the machine for multiple projects. They're also a great choice if you aren't sure what you'll need for your next project.

The OF16Pro is an excellent example of a multi-use tool. The machine comes with multiple attachments and heads that allow it many functions. It can be used for grinding, sanding, or polishing either wood or concrete.

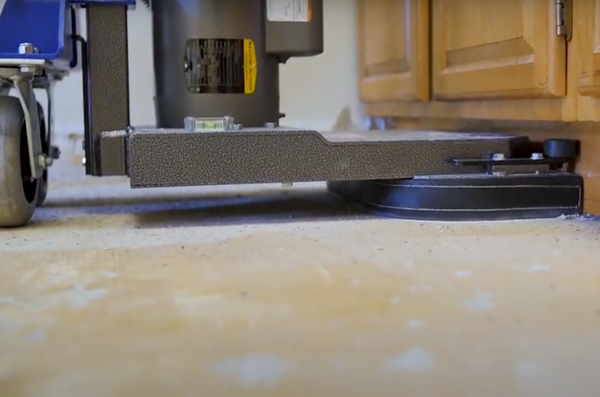

Find a Complimentary Floor Edger

When working on a project with any hard-to-reach areas, a floor edger is necessary. Examples of difficult areas include beneath overhangs or shelving units and around permanent fixtures. A floor edger is explicitly designed to reach these areas without causing damage to walls or fixtures.

The OFEdge 120 18" Floor Edger is a great choice for both beginners and experienced contractors. The edger is designed to go as low as 4" and reach as deep as 11". It's equipped with unique edging wheels and a maneuverable head that gets into even the most problematic areas.

Do You Have More Questions About Choosing the Right Wood Floor Sander?

Choosing the right floor sander for your project is crucial. For wood, you need to look for a machine that balances power with a low speed to not damage the material. Always choose a machine that falls within your experience level.

Do you have more questions about choosing the right wood floor sander?

Check out our selection of machines designed to work on wood flooring and decks. This will help you gain a better understanding of currently available options for your next project.

4 comments